Pharmaceutical Aluminum Products Center

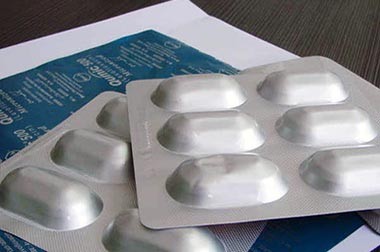

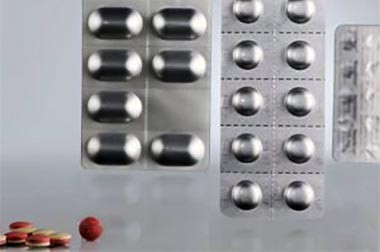

Aluminum Blister Packaging

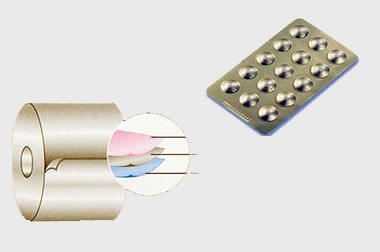

Pharmaceutical blister packaging is a process that involves forming hard sheet materials into blister shapes through thermal or cold processing, filling the blisters with medication, and finally heat-sealing a cover material to the blister material, creating a complete medication packaging system.

Cold Forming Foil

Cold-forming aluminum foil is a laminated composite material known for its high barrier properties, easy formability, and resistance to cracking or delamination.

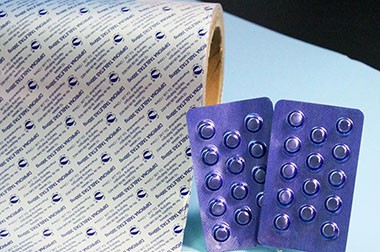

Pharmaceutical PVC Film

In blister packaging, PVC is commonly used as the forming material to create cavities for holding products such as tablets or capsules. PVC (polyvinyl chloride) is a plastic known for its durability and versatility.

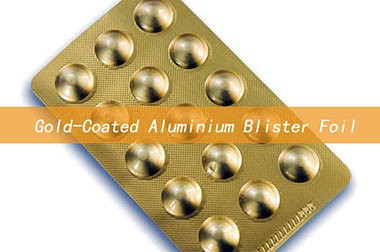

Pharmaceutical PTP aluminum Foil

Pharmaceutical PTP (Push-Through-Package) aluminum foil is a specialized type of packaging material used primarily in the pharmaceutical industry for blister packaging.

Pharmaceutical Tropical Aluminum

Tropical foil serves as a barrier layer in plastic packaging, effectively protecting moisture-sensitive products from moisture, oxygen, light, and UV damage.

Pharmaceutical Double aluminum easy tear film

Pharmaceutical Double Aluminum Easy Tear Film is a high-performance packaging material that combines easy-tear film and adhesive layer technology, specifically designed for pharmaceutical packaging.

Pharmaceutical aluminum composite film

Pharmaceutical aluminum composite films generally include pharmaceutical aluminum-plastic composite films, paper-aluminum pharmaceutical composite films, aluminum-aluminum composite films, aluminum-plastic-paper composite films, aluminum-polyester composite films, and aluminum-aluminum blister composite films.

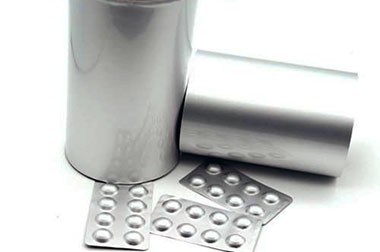

Aluminium Foil for Pharmaceutical Packaging

The reason medicines are packed in aluminium foil is closely related to the excellent physical and chemical properties of aluminium foil. Aluminium foil packaging not only effectively protects medicines from adverse external factors but also enhances their safety and stability, making it an essential material in pharmaceutical packaging.