8011 Aluminum Foil for Pharmaceutical Packaging

Pharmaceutical packaging 8011 aluminum foil is a specialized packaging material made from 8011 aluminum alloy. 8011 aluminum foil is especially suitable for blister packaging, strip packaging, and heat-seal films. Its composition and properties make it an ideal choice for protecting medications from environmental factors that may affect their efficacy.

8011 aluminum foil, with its excellent barrier properties, corrosion resistance, and formability, is widely used in pharmaceutical packaging. This alloy has good strength and flexibility, making it an ideal choice to protect sensitive medications from the effects of moisture, oxygen, and light.

8011 aluminum foil is a high-performance foil material specifically designed for pharmaceutical packaging. It is widely used in the packaging of pharmaceuticals, medical devices, nutritional supplements, and other fields. Its superior moisture, light-blocking, and gas-barrier properties effectively protect medications from environmental influences, extend the shelf life of medications, and ensure their stability and safety.

8011 aluminum foil also has good processing properties, making it suitable for various printing and coating treatments. It is highly adaptable and can meet the diverse packaging needs of pharmaceuticals.

8011 aluminum foil provides excellent protection, extends product shelf life, and can be customized according to customer requirements to meet different pharmaceutical packaging needs.

8011 Pharmaceutical Aluminum Foil Features

- Moisture Resistance: 8011 aluminum foil has excellent moisture resistance, effectively isolating moisture from the air, preventing medications from deteriorating or losing efficacy due to a humid environment.

- Light Blocking: The metal surface blocks ultraviolet and visible light, preventing medications from degrading or losing efficacy under light exposure, especially suitable for light-sensitive drugs.

- Gas Barrier: 8011 aluminum foil has strong gas barrier properties, effectively blocking oxygen, nitrogen, and other gases, ensuring the chemical stability of medications.

- Ductility and Tensile Strength: 8011 aluminum foil has good ductility, making it easy to form during production. At the same time, its high tensile strength ensures that it will not tear or break during the heat sealing and packaging process.

- Printability: The aluminum foil has good printability, making it suitable for printing, coating, and other surface treatments. It can clearly print important information such as the brand, usage instructions, etc., enhancing the appearance and functionality of the packaging.

- Pinhole Standard: Strict quality control limits the pinhole diameter to ≤0.3 mm, with a maximum of ≤5 pinholes per square meter, minimizing the risk of contamination.

- Non-toxic and Safe: Complies with FDA, GMP, and ISO standards, with heavy metal content ≤0.25 ppm, and has undergone strict hygiene testing.

- Heat Sealability: Can effectively bond with PVC, PVDC, and other polymers at temperatures between 130-200°C, ensuring airtightness in blister packaging.

Technical Parameter of 8011 Pharmaceutical Aluminum Foil

| Product name | 8011 Aluminum Foil for Pharmaceutical Packaging |

| Alloy-temper | 8011-O H18 |

| Thickness | 0.02mm(20micron) - 0.03mm (30micron) (tolerance:±5%) |

| Width and tolerance | 120- 1500 mm (tolerance:± 1.0mm) |

| Weight | 80 - 250kg per roll coil (or customized) |

| Surface | one side matte, one side bright |

| Surface quality | 1. Free of black spot, line mark, creases, wrinkles, etc |

| 2. Rell: no air packet, no bumps, etc | |

| Core material | Steel / aluminum / paper |

| Core ID | 76mm, 152mm (±0.5mm) |

| Packaging | Fumigation free wooden cases for the Blister foil for pharmaceutical aluminium foil paper manufacture in China low price |

| Tensile Strength(Mpa) | 45-110MPa (according to thickness) |

| Elongation % | ≥1% |

| Wettability | A grade |

| Surface wetting tension | ≥32dyne |

| Application | used in pharmaceutical packing, medical packaging , Medicine pack etc |

8011 Aluminum Foil Surface Treatment

The surface treatment of 8011 aluminum foil is highly versatile, including heat sealing, printing, coating, and more, to meet the diverse needs of pharmaceutical packaging. The 8011 aluminum foil produced by HC Aluminum has a clean surface, uniform color, and is free from spots and holes, ensuring the stability and consistency of the packaging quality. At the same time, HC Aluminum also offers customized aluminum foil based on customer requirements, ensuring precise compliance with the specific packaging needs of different pharmaceuticals.

Aluminum Alloy 8011 Foil Chemical Properties

8011 aluminum foil mainly contains elements such as Fe, Si, and others. The 8011 aluminum foil produced by HC Aluminum has a clean surface, uniform color, and is free from spots and holes, and can be customized according to customer requirements.

8011 aluminum foil is primarily composed of aluminum (Al), iron (Fe), and silicon (Si) elements. The addition of iron and silicon improves its strength and corrosion resistance, allowing the foil to withstand greater mechanical stress during the packaging process and provide additional protection. Generally, the Fe content is typically below 0.5%, while the Si content is about 0.2%.

| Al | Reminder |

| Si | 0.50 – 0.90 |

| Fe | 0.60 – 1 |

| Cu | ≤ 0.10 |

| Mn | ≤ 0.20 |

| Mg | ≤ 0.050 |

| Cr | ≤ 0.050 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.080 |

Mechanical Properties of 8011 Aluminum Foil

| Alloy | Temper | Thickness (mm) | Tensile Strength (Mpa) | Elongation (%) A50mm | Elongation (%) A100mm |

| 8011 | O | 0.006-0.009 | 50-100 | – | 0.5 |

| >0.009-0.025 | 55-100 | – | 1 | ||

| >0.025-0.04 | 55-110 | – | 4 | ||

| >0.04-0.09 | 60-120 | – | 4 | ||

| >0.09-0.14 | 60-120 | 13 | – | ||

| >0.14-0.2 | 60-120 | 15 | – | ||

| H18 | 0.035-0.2 | ≥160 | – | – | |

| H19 | 0.035-0.2 | ≥170 | – | – | |

| H22 | 0.035-0.04 | 90-150 | – | 1.0 | |

| >0.04-0.09 | 90-150 | – | 2.0 | ||

| >0.09-0.14 | 90-150 | 5 | – | ||

| >0.14-0.2 | 90-150 | 6 | – | ||

| H24 | 0.035-0.04 | 120-170 | 2 | – | |

| >0.04-0.09 | 120-170 | 3 | – | ||

| >0.09-0.14 | 120-170 | 4 | – | ||

| >0.14-0.2 | 120-170 | 5 | – |

8011 Pharmaceutical Aluminum Foil Temper

8011 O Pharmaceutical Aluminum Foil

8011 O aluminum foil is an annealed foil that is widely used in pharmaceutical packaging, especially as a material for drug packaging. This aluminum foil is typically supplied in coil form and is processed into pharmaceutical packaging materials, such as blister packaging for tablets, pill packaging bags, and more.

8011 H18 Pharmaceutical Aluminum Foil

8011 H18 aluminum foil is a hardened foil (H18 temper) that is commonly used in pharmaceutical packaging applications requiring higher hardness and tear resistance. Compared to O temper foil, H18 foil is more rigid and durable, making it suitable for packaging applications with higher strength requirements.

8011 O Pharmaceutical Aluminum Foil: Features good flexibility and high moisture resistance, making it suitable for most pharmaceutical packaging needs, especially for packaging that requires protection from light, moisture, and oxygen.

8011 H18 Pharmaceutical Aluminum Foil: Offers higher hardness and strength, making it ideal for pharmaceutical packaging requiring high tear resistance and mechanical pressure resistance. It is commonly used in aluminum foil seals or more structured packaging.

Below is a comparison table of 8011 O and 8011 H18 aluminum foils:

| Characteristics/Parameters | 8011 O Pharmaceutical Aluminum Foil | 8011 H18 Pharmaceutical Aluminum Foil |

| Temper | O (Annealed) | H18 (Hardened) |

| Hardness | Softer, suitable for forming and processing | Harder, suitable for high-strength packaging requirements |

| Tear Resistance | Lower, but sufficient for standard packaging needs | Higher, suitable for applications requiring high tear resistance |

| Light Blocking | Good, effectively blocks UV and visible light | Good, same light-blocking performance as O temper |

| Moisture Resistance | Good, effectively blocks moisture | Good, same moisture resistance as O temper |

| Gas Barrier | Excellent, prevents oxygen and moisture from entering packaging, protecting the pharmaceutical product | Excellent, same gas barrier properties as O temper |

| Odor Protection | Good, prevents external odors from affecting the drug's flavor | Good, same odor protection as O temper |

| Formability | Excellent, easy to process into deep-formed products, such as pharmaceutical blister packaging | Poorer, requires precise processing equipment, suitable for structural packaging such as bottle sealing |

| Suitable Packaging Types | Pharmaceutical blister packs, tablets, ointments, bags, etc. | High-strength pharmaceutical packaging, aluminum foil bottle caps, aluminum foil seals, etc. |

| Application Fields | Mainly used in pharmaceutical aluminum foil packaging, such as tablet packaging, blister packaging, etc. | Used in high-strength pharmaceutical packaging, such as bottle sealing, aluminum foil sealing, etc. |

Through this table, you can clearly see the main differences and applicable scenarios between the two types of aluminum foil. 8011 O aluminum foil is suitable for general pharmaceutical packaging, while 8011 H18 aluminum foil is more suitable for special packaging requiring higher strength and tear resistance.

8011 Pharmaceutical Aluminum Foil Applications

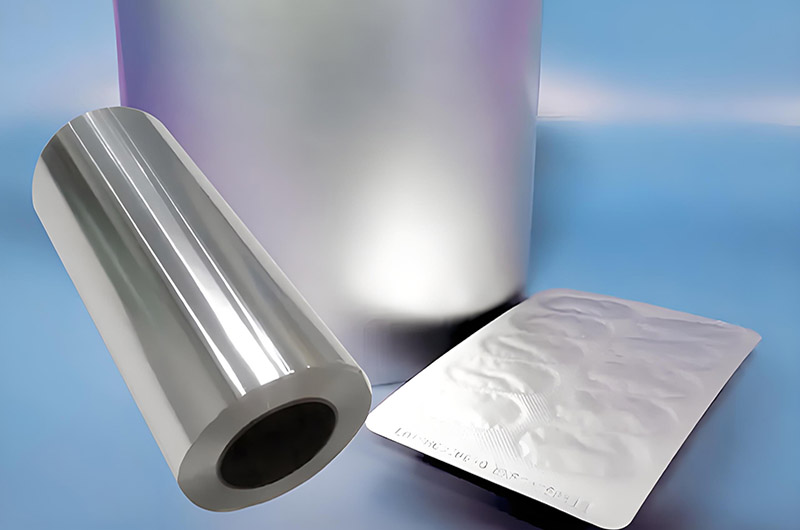

8011 aluminum foil for blister packaging

Blister packaging is one of the most common forms of pharmaceutical packaging, especially suitable for tablets, capsules, powders, and more. 8011 aluminum foil, with its excellent moisture resistance, light-blocking, and gas barrier properties, effectively protects the pharmaceutical product from moisture, air, and light, thus extending its shelf life and stability. The common tempers for 8011 aluminum foil are O (annealed soft state) and H18 (hardened state), both of which provide good formability and mechanical properties, suitable for various blister packaging needs.

Key advantages:

- Moisture resistance: 8011 aluminum foil effectively prevents moisture penetration, keeping the pharmaceutical product dry.

- Light-blocking: The aluminum foil blocks light, preventing degradation caused by exposure to light.

- Gas barrier: Effectively blocks oxygen and other gases, preventing oxidation or degradation of the pharmaceutical product.

Blister Packaging (PTP 8011 Aluminum Foil)

| Item | Description |

| Application | Sealing of tablets and capsules, used for single-dose packaging to reduce contamination during consumption. |

| Structure | Composed of three layers: |

| OP Protective Layer: Provides protection, preventing the drug from contacting the external environment. | |

| Aluminum Foil Base Material: Provides sealing, barrier, and protects the drug from moisture, oxygen, and light. | |

| VC Adhesive Layer: Acts as an adhesive, bonding the aluminum foil with PVC/PVDC hard sheets, ensuring the integrity of the packaging. | |

| Thickness | 0.025mm to 0.08mm (customizable according to requirements). |

| Material Composition | Composite of aluminum foil and PVC/PVDC plastic hard sheets. |

| Advantages | Single-dose packaging: Makes it easier for consumers to take the correct dose, reducing waste. |

| Reduces contamination: Effectively isolates external contamination sources, ensuring the purity and safety of the drug. | |

| Extends shelf life: Excellent barrier properties help extend the shelf life of the drug, especially for drugs sensitive to moisture and light. | |

| Application Field | Pharmaceutical packaging, especially for oral medications, capsules, vitamins, etc. |

8011 Aluminum Foil for Strip Packs

Strip packs are mainly used for packaging small-dose pharmaceuticals, such as tablets and capsules, where the pharmaceutical products are arranged in a strip of aluminum foil bags. 8011 aluminum foil provides excellent protective performance in such packaging, preventing external environmental factors (such as moisture and oxygen) from affecting the pharmaceutical products and maintaining their long-term stability.

Key advantages:

- Maintains product stability: By providing a strong physical barrier, it preserves the active ingredients and quality of the pharmaceutical products.

- Convenience: Strip packaging is easy for distribution and use, suitable for everyday pharmaceutical storage.

8011 Aluminum Foil in Medical Device Packaging

Due to its excellent physical protective properties, 8011 aluminum foil is also widely used in medical device packaging. It effectively prevents external factors (such as air, moisture, bacteria, etc.) from contaminating medical devices, ensuring the safety and hygiene of the devices. It is especially used for disposable medical devices such as needles, syringes, and surgical instruments, providing necessary protection to prevent damage during storage and transportation.

Key advantages:

- Protective performance: 8011 aluminum foil provides sealed protection for medical devices, preventing external contamination.

- Antibacterial properties: The surface of the aluminum foil is less prone to bacterial growth, providing higher hygienic protection for medical devices.

- High durability: It can withstand various environmental changes during transportation and storage, ensuring the safety of devices during use.

8011 Aluminum Foil in Nutritional Supplement Packaging

Many nutritional supplements, such as vitamins, mineral supplements, herbal preparations, etc., use 8011 aluminum foil as their packaging material. These products typically need to maintain long-term stability and freshness, avoiding the effects of oxidation and moisture on product quality. 8011 aluminum foil, with its excellent moisture resistance, oxygen barrier, and light resistance, makes it an ideal packaging choice that effectively extends the shelf life of the supplements.

Key advantages:

- Extended shelf life: 8011 aluminum foil helps preserve the potency of supplements through its excellent gas barrier properties.

- Freshness protection: The aluminum foil effectively prevents moisture and oxygen from entering, ensuring the freshness of the supplements.

- Environmental friendliness: Aluminum foil is recyclable, meeting environmental requirements.

Advantages of 8011 Aluminum Foil Over Other Alternatives

- Superior to pure aluminum: Due to the addition of alloy elements such as iron and silicon, it has higher mechanical properties (e.g., tensile strength).

- Cost-effective: Combines high performance with a competitive price, making it an ideal choice for large-scale pharmaceutical production.

- Sustainability: Fully recyclable and lightweight, reducing environmental impact.

8011 aluminum foil is an indispensable material in pharmaceutical packaging, providing unparalleled protection, compliance, and versatility. It integrates with modern sealing technologies and meets strict safety standards, making it a cornerstone for drug preservation and patient safety.

8011 Pharmaceutical Aluminum Foil Quality Standards and Considerations

When selecting 8011 aluminum foil for pharmaceutical packaging, the following factors must be considered:

- Pinhole Density: The aluminum foil should minimize the number of pinholes to maintain its barrier properties.

- Surface Cleanliness: A clean surface ensures proper sealing and printing.

- Compliance: Ensure that the aluminum foil meets the relevant pharmaceutical standards and certifications.

Adhering to these standards ensures that the aluminum foil effectively protects the drugs.

HC 8011 Pharmaceutical Aluminum Foil Quality

- Surface Quality: Clean, free from scratches, black oil spots, insects, or other defects, with neat edges and no burrs.

- Pinhole Control: Strictly prevents pinholes or holes to ensure barrier performance.

- Processing State: Common soft state (O state) or hard state (H18), thickness range 0.02-0.2mm, custom width available.

8011 aluminum foil is a reliable and cost-effective pharmaceutical packaging material, effectively resisting environmental factors. Its versatility and compliance with industry standards make it the first choice for various pharmaceutical packaging needs.