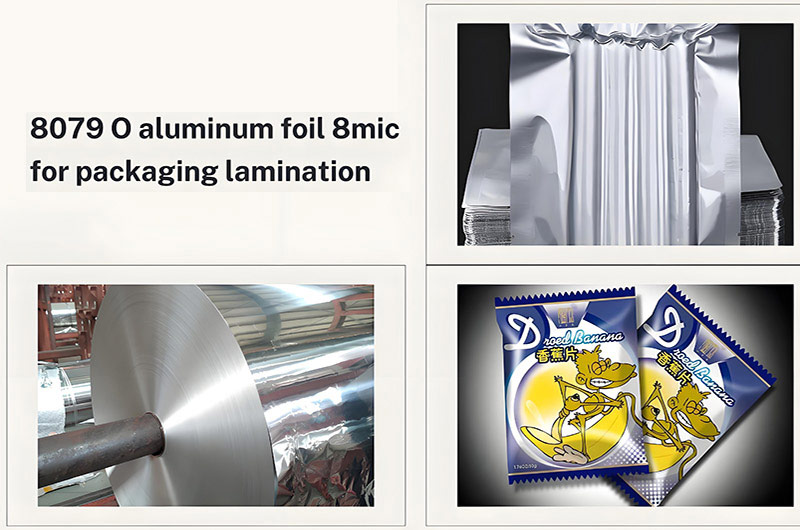

8079 Aluminum Foil for Pharmaceutical Packaging

8079 aluminum foil possesses exceptional flexibility and corrosion resistance, making it ideal for the packaging of various pharmaceuticals. 8079 aluminum foil is mainly used in soft packaging, blister packaging, and other types of pharmaceutical packaging. With its excellent physical properties, it is widely used in the pharmaceutical industry to ensure the quality, shelf life, and safety of medicines.

8079 aluminum foil has outstanding barrier properties, effectively blocking moisture, oxygen, and light from damaging the medicines, ensuring the quality and safety of the pharmaceuticals during storage.

8079 aluminum alloy foil is widely used to produce various types of aluminum alloy foils, available in H14, H18, and other temper states, with thicknesses ranging from 10 to 200 microns, offering excellent performance for many applications. 8079 aluminum foil is a flexible and unique metal with a soft temper and an attractive surface. It is an ideal product for applications that require higher tensile strength materials, ensuring that the pharmaceutical packaging process remains unaffected.

8079 aluminum foil is a specially designed product, primarily used for high-end packaging applications, especially in the pharmaceutical industry. Its unique alloy formulation and annealing options make it an excellent barrier material, capable of protecting the active ingredients in drugs from moisture, oxygen, and light exposure. Compared to pure aluminum foil or other traditional alloys, 8079 has higher mechanical strength and better formability, which is crucial for precise applications such as blister packaging and small pouch packaging.

8079 pharmaceutical packaging aluminum foil is primarily used for blister packaging of pharmaceutical capsules and tablets, as well as for packaging of powder, granules, and liquids.

8079 Aluminum Foil Properties

- High Flexibility: 8079 aluminum foil has extremely high flexibility, allowing it to adapt to various shapes during the packaging process. Compared to traditional aluminum foil, 8079 aluminum foil shows better mechanical performance in processes like folding, rolling, and thermoforming.

- Corrosion Resistance: It exhibits excellent resistance to chemicals, protecting against moisture, air, and other corrosive substances, thereby providing effective protection for pharmaceuticals. Its corrosion resistance ensures that the packaged medicines remain unaffected by external factors for long periods.

- Outstanding Barrier Properties: 8079 aluminum foil provides excellent barriers against moisture, oxygen, and light. This is particularly important for pharmaceuticals, as moisture, oxygen, and light can affect their stability, activity, and shelf life. Medicines in packaging are well protected, preserving their effectiveness and quality.

- High Tensile Strength: After tempering, 8079 aluminum foil exhibits high tensile strength, making it suitable for pharmaceutical packaging that requires strong pressure and stretch resistance. Even under pressure or impact during the packaging process, 8079 aluminum foil maintains its integrity.

- Tensile strength and flexibility: Compared to alloys like 8011, 8079 has higher strength, allowing it to withstand mechanical stress during packaging and transportation without tearing.

- Formability: (e.g., H18) Easily formed into blister packs, collapsible tubes, and pouches.

- Aesthetic Surface: 8079 aluminum foil has a smooth and uniform surface with an attractive appearance, making it suitable for various printing and surface treatments. Text and graphics on the packaging are clearly presented, enhancing the visual appeal of the pharmaceutical packaging.

Aluminum Alloy 8079 Foil Specification

| Property | Details |

| Product | Pharmaceutical Foil |

| Material | Aluminum Alloy 8079 |

| Type | Bare, Mill Finish |

| Temper | H14, H18 |

| Standard | QQA-1876, ASTM B479 |

| Thickness | 0.00018 to 0.064 in (0.00457 to 1.625 mm) |

| Width | 0.375 to 60 in (9.525 to 1524 mm) |

| Length | Coil |

8079 Aluminum Foil Alloy Composition and Annealing Options

Composition:

8079 belongs to the 8000 series of aluminum alloys. Typically, its composition is primarily aluminum (purity ≥ 99.35%), with small amounts of elements such as silicon and iron carefully added. These trace alloying elements enhance the mechanical properties and corrosion resistance of the aluminum foil without compromising its barrier performance.

Annealing Options:

The foil is available in various annealing conditions—common annealing states include soft (O) and various hard or partially hard conditions (H14, H18, etc.). The soft (O) condition provides the highest formability, making it ideal for applications requiring excellent shape conformity (such as adhering to irregular shapes), while the H-series anneals offer higher tensile strength and greater resistance to deformation during the packaging process.

8079 Aluminum Foil Barrier Properties

- Moisture, oxygen, and light resistance: One of the standout features of 8079 aluminum foil is its excellent barrier performance. It forms an airtight seal that prevents moisture and oxygen—two key factors in drug degradation. Additionally, it blocks light (especially UV light), helping to protect light-sensitive drugs and extend product shelf life.

- Surface Properties: The surface of 8079 aluminum foil can present a uniform silver-white sheen, which is not only aesthetically pleasing but also ideal for printing important information (such as production dates, batch numbers, and expiration dates).

Aluminum Alloy 8079 Foil Chemical Properties

8079 aluminum alloy is a high-strength, low-oxidation aluminum alloy, primarily composed of aluminum with small amounts of iron and silicon, offering excellent mechanical properties and corrosion resistance.

| Al | Reminder |

| Si | 0.50 - 0.30 |

| Fe | 0.70 – 1.3 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.10 |

| Other | ≤ 0.15 |

Mechanical Properties Of 8079 Aluminum Foil

| Alloy &Temper | Thickness (Mm) | Tensile Strength (N/Mm²) | Elongation (%) | Pinholes Per M2 | Surface Wettability |

| 8079-O | 0.006 | 50-110 | ≥1.5 | <500 | A |

| 8079-O | >0.006 – 0.0065 | 60-110 | ≥1.5 | <400 | A |

| 8079-O | >0.0065 – 0.007 | 60-110 | ≥2 | <200 | A |

| 8079-O | >0.007 – 0.009 | 70-110 | ≥2 | <100 | A |

8079 Pharmaceutical Aluminum Foil Applications

8079 aluminum foil is widely used in the pharmaceutical packaging industry due to its exceptional barrier, moisture resistance, and airtight properties. It not only ensures the stability and safety of pharmaceuticals but also improves the convenience and usability of packaging.

| Application | Description |

| Pharmaceutical Blister Packaging | 8079 aluminum foil, used as blister packaging material, provides excellent moisture and oxidation protection, effectively extending the shelf life of pharmaceuticals while making it easy for patients to identify the medication and improve convenience. |

| Pharmaceutical Sachet Packaging | 8079 aluminum foil is used for sachet packaging of powders, granules, and liquid medications, effectively preventing moisture and oxygen from entering, ensuring the stability of the drug's ingredients during long-term storage, and preserving its efficacy. |

| Airtight Packaging | 8079 pharmaceutical aluminum foil is commonly used for producing sealing strips due to its excellent sealing properties, providing efficient airtight protection, preventing moisture, oxidation, and bacterial contamination, and ensuring the stability of the pharmaceutical ingredients, thus extending shelf life. |

Pharmaceutical Blister Packaging 8079 Aluminum Foil

8079 aluminum foil is widely used in pharmaceutical blister packaging, particularly for packaging tablets and capsules. This foil, due to its excellent moisture, oxidation resistance, and good barrier properties, effectively protects the medication from external environmental influences. Blister packaging not only extends the shelf life of the pharmaceutical but also ensures the stability of the drugs during transportation and storage. Additionally, blister packaging is easy to handle, allowing patients to easily identify the medications and simplifying the process by removing each pill individually, thus increasing patient convenience.

8079 Aluminum Foil for Pharmaceutical Sachet Packaging

8079 aluminum foil is also commonly used for sachet packaging of pharmaceuticals, especially for powders, granules, and liquid medications. In this application, 8079 aluminum foil provides excellent moisture and barrier properties, effectively preventing the intrusion of moisture, oxygen, and other external factors, thus keeping the active ingredients intact. Using this aluminum foil for packaging ensures the long-term stability of the medication and prevents deterioration or loss of efficacy, ensuring the safety and effectiveness of the product in the hands of consumers.

Airtight Packaging 8079 Aluminum Foil

Due to its exceptional sealing properties, 8079 aluminum foil is commonly used in pharmaceutical packaging to produce sealing strips. This foil provides efficient airtight protection, preventing moisture, oxygen, and bacterial contamination, ensuring the stability of the pharmaceutical ingredients. Particularly for medications that need to be kept away from air exposure (such as sensitive chemicals or biological products), 8079 aluminum foil’s airtight packaging is critical. It not only preserves the efficacy of the pharmaceuticals but also extends the shelf life, keeping the products in optimal condition during use.

Advantages of 8079 Aluminum Foil

- Extends Medication Shelf Life: Due to its outstanding barrier properties, 8079 aluminum foil significantly extends the shelf life of pharmaceuticals, maintaining their effectiveness and safety. This is especially important for medications that are sensitive to environmental factors (such as drugs containing active ingredients).

- Meets Strict Pharmaceutical Industry Standards: 8079 aluminum foil typically meets various industry standards required for pharmaceutical packaging, such as FDA, ISO, etc. It ensures that the packaging not only effectively protects the medication but also complies with industry regulations, ensuring both product quality and consumer safety.

- Enhanced processing performance: The high ductility and excellent formability of 8079 aluminum make it easy to integrate into high-speed automated packaging lines.

- Aesthetics and printability: Its smooth, shiny surface is perfect for high-quality printing and brand promotion, which is crucial in consumer-facing product markets.

- Environmentally Friendly: As a recyclable metal material, 8079 aluminum foil offers excellent environmental benefits when recycled after use, helping reduce the impact of packaging waste on the environment.

8079 aluminum foil is a high-performance material used for pharmaceutical packaging, designed to protect sensitive medications. Its customized composition and processing methods give it superior barrier properties, mechanical strength, and compliance with safety regulations—all of which meet the requirements of modern pharmaceutical packaging. Whether used for blister packaging, small pouch packaging, or as a sealing layer in composite packaging, 8079 aluminum foil ensures product integrity, extends shelf life, and meets environmental and safety standards.

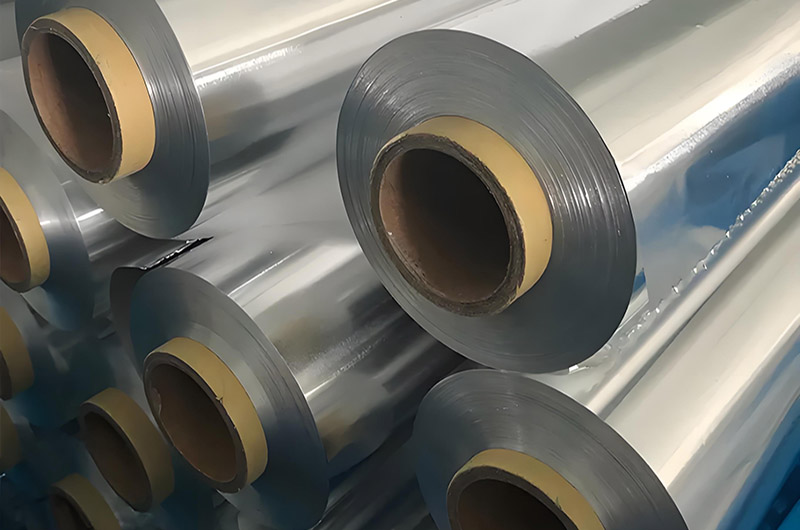

8079 Aluminum Foil Processing

- Rolling and Cutting: 8079 aluminum foil undergoes a rolling process during production to ensure uniform thickness, allowing it to be cut to the required sizes as needed.

- Thermoforming: In pharmaceutical packaging production, 8079 aluminum foil can be thermoformed into containers or covering layers for various blister packaging, sachet, and sealed packaging needs.

- Printing and Surface Treatment: 8079 aluminum foil can undergo printing or other surface treatments to meet aesthetic packaging requirements, such as printing medication names, production dates, expiration dates, etc.

Due to its excellent physical properties, especially the outstanding protection it provides in pharmaceutical packaging, 8079 aluminum foil has become an indispensable material in the pharmaceutical industry. It effectively extends the shelf life of pharmaceuticals, ensuring that the medication’s quality remains unaffected by external factors, while also offering good processability and an attractive appearance. Whether in blister packaging, sachet packaging, or airtight sealing, 8079 aluminum foil is the ideal choice for providing safe, effective, and high-quality pharmaceutical packaging.

HC 8079 Aluminum Foil Processing and Quality Considerations

HC 8079 Aluminum Foil Manufacturing Precision

8079 aluminum foil is produced using carefully controlled rolling and annealing processes. These steps ensure precise thickness control—typically between 0.015 mm and 0.2 mm—to meet the stringent requirements of pharmaceutical applications. Quality control is critical; advanced online inspection systems monitor defects that may compromise barrier integrity, such as pinholes, wrinkles, or contamination.

HC 8079 Aluminum Foil Quality Requirements

- Surface clean and flat, free from pinholes, scratches, black oil spots, or other defects.

- Neat edges, free from burrs, tower-shaped edges, or leaf-shaped edges.

- Heavy metal content ≤ 0.25 ppm, water-wash performance meets A-grade standards.

8079 Aluminum Foil Superior to Competing Materials

- Enhanced durability: Its elongation and tensile strength are superior to 8011 foil, making it more crack-resistant during high-speed packaging processes.

- Environmental sustainability: Fully recyclable, reducing waste and complying with environmental initiatives.

- Versatility: Can be laminated with materials such as PET, BOPP, and CPP, offering composite packaging solutions.