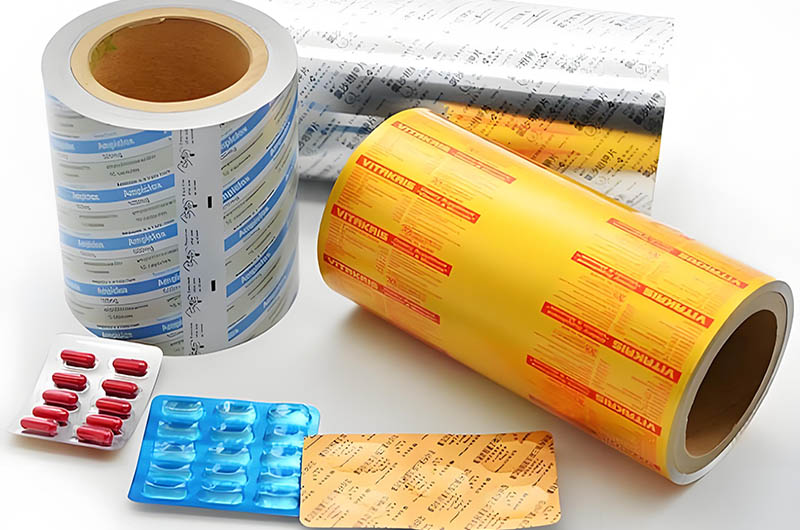

Aluminium Blister Foil

Aluminium blister foil is a specialized packaging material widely used in the pharmaceutical industry for protecting solid dosage forms such as tablets and capsules. It serves as the sealing layer in blister packaging, ensuring the safety, stability, and shelf life of the medication.

Aluminium blister foil (also known as pharmaceutical blister foil or PTP foil) is a composite aluminium foil material specifically designed for pharmaceutical and health supplement packaging. Its core functions are to provide high barrier properties, light shielding, and sealing performance to ensure the stability and safety of the contents.

Aluminium Blister Foil Specifications

| Item | Specification Description |

| Alloy and Temper | Pharmaceutical-grade aluminium alloys: 8011, 8021, 8079 |

| Temper: | |

| O temper (soft): offers greater ductility and enhances child-resistant features | |

| H18 temper (hard): commonly used in Europe, thickness usually 25–30μm, facilitates easy push-through for medication access | |

| Thickness Range | Standard thickness: 20–30 microns (0.02–0.03 mm) |

| Customizable thickness: 0.015–0.08 mm | |

| Coating Type | Heat Seal Lacquer: |

| Suitable for heat sealing with PVC, PVDC, and other blister materials | |

| Coating weight: 4–8 GSM, ensuring excellent sealing performance | |

| Printing layer and coating surface treatment: | |

| One side printable for medication information (e.g., expiration date) | |

| Matte surface specially treated to enhance adhesion | |

| Compatibility with Blister Materials | Compatible with commonly used plastic blister materials such as PVC, PVDC, and PP |

| Packaging Feature Supplement | H18 hard foil is suitable for “easy push-through” dispensing |

| O temper soft foil supports child-resistant packaging design |

Aluminium Blister Foil Structure and Composition

Typical Structure of Aluminium Blister Foil

Aluminium blister foil is typically a multilayer composite material. Common structures include:

- Outer protective layer: biaxially oriented polyamide film (BOPA) or polyester film (PET), used to enhance mechanical strength and printing adaptability

- Middle aluminium foil layer: aluminium foil with thickness ranging from 0.04–0.075 mm (commonly using alloy grades 8021, 8079, or 8011), providing core barrier properties

- Inner heat seal layer: polyvinyl chloride (PVC), polyvinylidene chloride (PVDC), or cold-seal adhesive (VC), used for heat sealing with plastic rigid sheets such as PVC/PVDC

Extended Structure of Aluminium Blister Foil (Tropical Blister Foil)

A cold-formed aluminium cover (aluminium-plastic-aluminium structure) is added to the traditional alu-plastic blister, further enhancing light-proof and moisture-proof performance

Aluminium Blister Foil Characteristics

- Excellent barrier properties: aluminium foil effectively blocks moisture, oxygen, light, and contaminants, protecting the integrity of the medication.

- Heat seal compatibility: aluminium foil is usually coated with heat-seal lacquer, allowing firm bonding with various blister packaging materials to ensure tamper-evident sealing.

- Formability: in cold forming applications (alu-alu blister packaging), aluminium foil can be shaped into complex cavities without compromising its barrier performance.

- Printability: the surface of aluminium foil allows easy printing of essential information such as product name, dosage, and brand identity, improving patient compliance and product recognition.

- Sustainability: aluminium is recyclable and meets environmental sustainability goals for pharmaceutical packaging.

Applications of Aluminium Blister Foil

- Push-Through Blister Packaging: Combines aluminium foil with plastic films (such as PVC) to form cavities sealed with foil, commonly used for tablets and capsules.

- Cold-Forming Blister Packaging (Alu-Alu Composite Packaging): Utilizes aluminium foil as both the base and lidding material, providing enhanced protection for moisture- and light-sensitive drugs.

- Strip Packaging: Individual doses are sealed between two layers of aluminium foil, suitable for powders and granules.

| Application Field | Specific Use Description |

| Pharmaceutical Packaging | Single-dose sealed packaging for solid formulations: Suitable for tablets, capsules, pills, etc., facilitating distribution and administration. |

| Protection of sensitive drugs: Especially suitable for light- and moisture-sensitive medications, such as vitamins and antibiotics, to ensure stability and efficacy. | |

| Health Products & Food | Health product packaging: Provides high-barrier protection for high-value products (such as fish oil and probiotics), preventing oxidation and deterioration. |

| Food packaging: Moisture-proof and light-blocking packaging for moisture-sensitive foods like candies and chocolates, extending shelf life. |

Advantages of Aluminium Blister Foil in Pharmaceutical Packaging

- Extended Shelf Life: Aluminium blister foil offers strong barrier properties that help preserve the effectiveness of medicines over time.

- Tamper Evidence: Unauthorized access is clearly visible, ensuring product integrity.

- Patient Convenience: Blister packs are lightweight, portable, and facilitate dose tracking.

- Regulatory Compliance: Meets stringent pharmaceutical packaging standards, including those set by the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA).

| Advantage Category | Description of Advantage |

| Barrier Properties | Completely blocks water vapor, oxygen, and UV light, preventing moisture absorption, oxidation, or photodegradation of drugs. |

| Superior barrier compared to single plastic materials, prolonging the drug’s shelf life. | |

| Mechanical Properties | Aluminium foil base must have high elongation (O temper) and tensile strength to adapt to cold forming processes (forming depth ≤ 7mm). |

| When laminated with plastic, it compensates for the lack of ductility in pure aluminium foil, reducing the risk of fracture caused by stress concentration. | |

| Processing Adaptability | Supports high-speed automated production and is compatible with heat sealing to rigid films like PVC and PP. |

| Surface can be printed and embossed, meeting branding and anti-counterfeiting requirements. |

Aluminium Blister Foil Production Process

Aluminium Blister Foil Production Flow

- Laminating: Under controlled heat and pressure, aluminium foil is laminated with heat seal coatings (e.g., VMCH/HSL).

- Printing: Product information is added using flexographic or rotogravure printing technologies.

- Forming and Sealing: Aluminium foil is cut and molded into blisters, filled with pharmaceuticals, and sealed with backing materials (paper/plastic) by heating (170-180°C) and applying pressure (2.8-5.6 kg/cm²).

- Quality Control: Rigorous inspection ensures no pinholes on the surface, proper seal strength (≥8 N/25 mm), and compliance with standards such as ISO and FDA.

Aluminium Blister Foil Production Techniques and Key Technical Points

| Category | Details |

| Substrate Selection | Main alloy series: 8xxx series: |

| 8021-O | |

| 8079-O | |

| 8011-O | |

| Key control parameters: | |

| Forming Dome Height | |

| Heat Seal Strength | |

| Forming Process | Thermoforming Blister: |

| Uses vacuum forming to mold plastic rigid films (e.g., PVC, PVDC, PP, etc.) | |

| Medication is filled after forming | |

| Aluminium foil is heat-sealed onto the formed blisters using sealing machines to create sealed packaging | |

| Cold Formed Foil: | |

| Aluminium foil is pressed with molds to form drug cavities | |

| Outer aluminium foil is laminated with the thermoformed blister for double protection | |

| Quality Inspection | Key inspection indicators: |

| Pinholes: High-barrier requirements demand extremely low pinhole rates | |

| Seal Strength: Ensures packaging integrity to prevent air or water leakage | |

| Barrier Property: Water vapor transmission rate ≤ 0.5g/m²·24h to prevent moisture from affecting drug stability |

Aluminium blister foil is indispensable in pharmaceutical packaging, balancing protection, usability, and regulatory compliance. Its diversity in alloy types, coatings, and design enables it to meet various industry needs and adapt to evolving safety and sustainability trends.

Aluminium blister foil is an essential part of modern pharmaceutical packaging, offering unparalleled protection and convenience. Its adaptability to various packaging formats and compliance with regulatory standards make it the preferred choice for ensuring the safety and efficacy of medications.