Aluminium Blister Foil with Primer Lacquer for Packaging

Primer lacquer aluminium blister foil is a specially designed aluminum foil material used for the packaging of medicines and health products. The material is coated with a primer lacquer layer, which enhances adhesion, especially in blister packaging applications. This coating significantly improves the bond between the product and the packaging surface, ensuring the integrity and protective function of the packaging.

Primer lacquer aluminium foil is commonly used for the packaging of medicines and health products, providing an additional protective barrier that helps maintain the freshness and stability of the drugs over time.

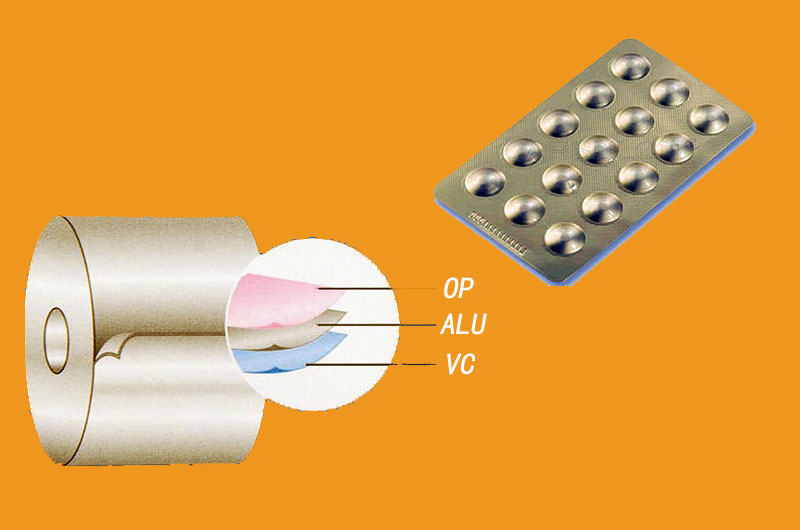

Primer lacquer aluminium blister foil Composition

- Aluminum foil substrate: Typically 25μm to 40μm thick aluminum foil, offering excellent barrier properties that effectively block light, oxygen, moisture, and other external factors to protect the product.

- Primer lacquer coating: The primer lacquer layer is applied to improve the surface adhesion of the aluminum foil, allowing subsequent inks, heat-seal coatings, or other layers to adhere firmly. The primer is usually made from polyester, polyurethane, or epoxy resin-based materials, offering excellent oxidation resistance, high-temperature resistance, and chemical stability.

- Surface coating treatments: The primer can undergo further surface treatments depending on specific application needs, such as protective layers or scratch-resistant coatings, enhancing the packaging’s wear resistance and corrosion resistance.

Primer lacquer aluminium blister foil Features

Function of the Primer Lacquer Coating

Enhanced adhesion: The primer lacquer coating provides an adhesive layer on the aluminum foil surface, helping to form a stronger bond between the product (such as tablets or capsules) and the packaging material, preventing separation or damage during packaging.

Improved compatibility with packaging: When in contact with PVC or other blister packaging materials, the primer lacquer coating effectively enhances the affinity between the two, improving sealing and preventing external environmental factors from affecting the drug's quality.

Protective Function

Freshness and stability: The aluminum blister film itself has excellent barrier properties, effectively preventing moisture, oxygen, light, and contaminants from entering, thereby extending the drug’s shelf life and ensuring its stability.

Physical protection: Blister packaging separates individual doses, reducing direct impact from external pressure and minimizing the risk of damage or contamination.

Environmental Friendliness and Durability

Durability: The aluminum blister film has strong tear resistance, tensile strength, and wear resistance, ensuring that the packaging remains intact during transportation and storage.

Recyclability: As an aluminum material, the blister film can be recycled after use, complying with environmental requirements.

Aluminium Blister Foil with Primer Lacquer Applications

Pharmaceutical Packaging

Pharmaceutical blister packaging: In pharmaceutical blister packaging, aluminum foil is combined with plastic films to form a strong sealed structure that effectively prevents moisture, oxidation, and contamination.

Stability and safety: The primer lacquer coating provides stronger protection, ensuring that the drug remains stable during storage and transportation, preventing external factors from affecting its quality.

Food Packaging

Food preservation: In the packaging of dietary supplements, candies, chocolates, biscuits, medicinal foods, and other food products, aluminum foil with a lacquer coating can block oxygen and moisture, preserving the freshness and extending shelf life.

Corrosion resistance: The primer lacquer coating enhances the aluminum foil’s resistance to corrosion, preventing any chemical reactions between the packaging and the food contents, ensuring food quality.

Daily Chemical Packaging

Cosmetics and skincare packaging: Aluminum foil with a lacquer coating can be used for high-end cosmetics packaging, including essential oils, perfumes, facial masks, and ointments, effectively preventing air and contaminants from entering, ensuring product stability and safety.

Temperature and chemical corrosion resistance: The primer lacquer coating has good temperature resistance, allowing it to withstand high-temperature steam or external environmental changes, preventing packaging from breaking or aging.

Selected Aluminum Foil Alloys

In applications of aluminum foil with primer lacquer, the most commonly used alloys are 8011 and 8079, which have good processability, ductility, and appropriate strength to meet the special requirements of pharmaceutical, food, and other packaging. The choice of alloy depends on the specific packaging requirements, such as ductility, strength, surface finish, and corrosion resistance.

Primer lacquer aluminium foil 8011

Characteristics: 8011 alloy is one of the most commonly used packaging aluminum alloys, offering excellent corrosion resistance, tensile strength, and processability.

Applications: 8011 alloy aluminum foil is widely used in food and pharmaceutical packaging, especially for blister packaging and food wrap packaging. It has high strength and is suitable for packaging requiring moisture and sealability.

Primer lacquer aluminium foil 8079

Characteristics: 8079 aluminum alloy is a high-strength aluminum alloy with excellent corrosion resistance and strong mechanical properties, making it particularly suitable for producing high-performance aluminum foils.

Applications: 8079 alloy is typically used in high-end pharmaceutical packaging, such as aerosol packaging, and in applications requiring superior sealing and protection performance. Due to its high tensile strength and excellent surface quality, it is suitable for aluminum foils with special performance requirements.

Aluminium Blister Foil with Primer Lacquer Advantages

- Excellent barrier properties: Aluminum foil itself has excellent resistance to gases, moisture, light, and odors, effectively protecting the contents from environmental influences.

- Enhanced adhesion: The primer lacquer coating significantly improves the adhesion of surface treatments, ensuring the stability of inks, printing, and other coatings.

- Excellent corrosion resistance: The coating enhances the aluminum foil’s resistance to corrosion, ensuring that the product remains stable inside the packaging for an extended period.

- Good heat sealability: This material has excellent heat-seal performance and can effectively seal with various plastic-based films, ensuring the integrity of the packaging.

Aluminium Blister Foil with Primer Lacquer Manufacturing Process

- Aluminum foil coating treatment: The aluminum foil surface is cleaned and treated, then coated with primer and cured. The coating is uniform and has strong adhesion, effectively reducing the risk of coating peeling.

- Printing and packaging: The coated aluminum foil can undergo various printing processes, such as screen printing and flexographic printing, for labeling, branding, and design presentation.

- Heat sealing and cutting: The coated aluminum foil material typically has excellent heat sealability, allowing it to be sealed with plastic films under heat, ensuring packaging integrity.