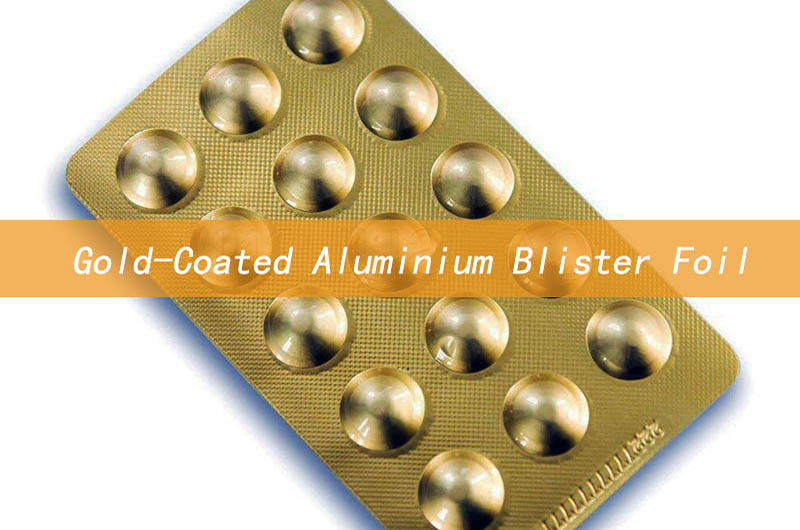

Gold-Coated Aluminium Blister Foil for Pharmaceutical Capsules and Tablets

Gold-coated aluminum foil is a premium material specifically designed for pharmaceutical blister packaging. It combines excellent barrier properties with an attractive appearance. Its golden surface not only enhances the high-end image of products but also effectively protects capsules and tablets from moisture, light, and other elements, making it ideal for high-end pharmaceutical products and branded medicines.

Gold-Coated Aluminium Blister Foil is an advanced blister packaging material specially designed for the pharmaceutical industry. With its high performance and elegant design, Gold-Coated Aluminium Blister Foil is the ideal choice for pharmaceutical packaging, providing comprehensive protection and market competitiveness for medications.

Structure of Gold-Coated Aluminium Blister Foil

- Structure: Composed of a primer coating, a high-purity aluminum base layer with a thickness of 18-30μm, and an HSL (heat seal lacquer) layer, offering a multi-layer protective structure.

- Material: Made of 8011 aluminum alloy, known for its excellent barrier and processing properties.

- Coating & Thickness: The surface is coated with a gold-colored layer, with thickness controlled between 18-30μm and a thickness tolerance of ±2%, ensuring uniformity and consistent packaging quality.

Features and Functions of Gold-Coated Aluminium Blister Foil

Manufactured using high-purity aluminum base material with a golden surface coating, it not only enhances visual appeal but also provides moisture and light protection, contributing to the preservation of active ingredients in medicines.

The golden coating enhances the premium appearance of the packaging, making it easier for consumers to distinguish different types of medications.

Barrier Properties: Effectively blocks moisture, oxygen, light, and other contaminants, ensuring the stability and active properties of capsules and tablets.

Heat Seal Performance: The HSL (heat seal lacquer) layer offers selectable coating densities (3-4gsm, 4-5gsm, 5-6gsm, 6-8gsm), compatible with PVC, PVC/PVDC, or cold-formed aluminum foil (Alu Alu), ensuring reliable sealing performance.

Product Information Table for Gold-Coated Aluminium Blister Foil

| Property | Details |

| Structure | Primer/AL18-30-hard/HSL |

| Temper | Hard |

| Alloy | 8011 |

| HSL Coating Weight | 3-4gsm; 4-5gsm; 5-6gsm; 6-8gsm |

| Treatment | Coated |

| Use | Pharmaceutical |

| Type | Roll |

| Thickness | 18-30µm |

| Thickness Tolerance | +/- 2% |

| Width | 80~750mm |

| Width Tolerance | +/- 3% |

| Packaging | PE Bag - Carton Box - Pallet - Stretch Film Wrapping |

| Inner Diameter (ID) | 76mm Or 152mm |

| Outer Diameter (OD) | ≤600mm |

| Colors | Up to 10 Colors |

| Minimum Order Quantity (MOQ) | 200kgs |

| Function | For heat sealing with PVC, PVC/PVDC, or Alu Alu cold forming foil to pack capsules, pills, or tablets |

| Producing Process | 1. Printing → 2. Laminating → 3. Curing → 4. Cutting → 5. Quality Inspection → 6. Packaging → 7. Delivery |

| Certification | FDA DMF/ISO |

| Sample Time | Within 7 Days |

| Delivery Date | 20~30 Days |

| Highlights | Pharma Aluminium Foil for Medicine Packaging, PTP Aluminum Foil Rolls, Aluminum PTP Blister Foils |

Applications of Gold-Coated Aluminium Blister Foil

Gold-Coated Aluminium Blister Foil is widely used in the pharmaceutical industry, especially for blister packaging of capsules, tablets, and granular medications. Its exceptional protective performance, visual appeal, and premium appearance make it an ideal choice for packaging high-end pharmaceutical products and branded medications.

Gold-Coated Aluminium Blister Foil is a common choice for packaging capsules, tablets, and granular medications. Blister packaging seals medications in aluminum foil blisters, providing effective protection against air, moisture, light, and contaminants, thereby ensuring the quality and shelf life of the medications. The aluminum foil material offers excellent barrier properties, effectively preventing moisture and oxidation while maintaining the stability of the medications.

With its outstanding barrier performance, exquisite design, and customizable options, Gold-Coated Aluminium Blister Foil becomes the ideal material for packaging high-end pharmaceutical products. It not only provides physical protection for medications but also extends their shelf life.

Processing and Advantages of Gold-Coated Aluminium Blister Foil

Gold-Coated Aluminium Blister Foil is the preferred material for pharmaceutical packaging due to its eco-friendly coating process, excellent adhesion, abrasion resistance, and heat-sealing performance. Its uniform aluminum foil thickness, good substrate compatibility, and efficient production process ensure consistent protection in drug packaging, enhancing brand image and ensuring drug stability. With these advantages, it meets the high standards of pharmaceutical packaging and provides strong support for the success of medicines in the market.

Processing of Gold-Coated Aluminium Blister Foil

| Processing | Detailed Description |

| Eco-Friendly Coating Process | Gold-Coated Aluminium Blister Foil uses non-toxic, eco-friendly coating materials, uniformly applied to the aluminum foil surface through advanced coating technology, ensuring strong adhesion and a uniform golden appearance. The entire coating process complies with global pharmaceutical packaging industry standards for safety and environmental protection, such as FDA DMF and ISO certifications. |

| Coating Adhesion and Abrasion Resistance | Through a special coating formulation, the adhesion of Gold-Coated Aluminium Blister Foil is enhanced, maintaining stability during processes such as extrusion, heat sealing, or printing. The coating has excellent abrasion resistance, ensuring that it remains intact during packaging, transportation, and storage, preserving its appearance and functionality. |

| Uniform Aluminum Foil Thickness | The aluminum foil thickness of Gold-Coated Aluminium Blister Foil is strictly controlled within the range of 18-30μm with a tolerance of ±2%. This uniformity provides a stable foundation for coating, heat sealing, and processing, contributing to the consistency of the final product. |

| Heat-Sealing Process | Gold-Coated Aluminium Blister Foil is compatible with various heat-sealing processes and substrates like PVC, PVDC, or PP. Through heat-sealing equipment, the aluminum foil is firmly bonded to the substrate, forming a sealed package that prevents the ingress of moisture and oxygen, protecting the stability and freshness of the medication. |

| Support for Multi-Color Printing | Gold-Coated Aluminium Blister Foil supports exquisite multi-color printing of up to 10 colors, allowing for the printing of brand logos, anti-counterfeiting information, and other designs based on customer needs. This enhances market recognition and satisfies the aesthetic demands of high-end packaging. |

| High-Efficiency Processing Workflow | The production process of Gold-Coated Aluminium Blister Foil includes coating, printing, heat sealing, cutting, quality inspection, and packaging. Each stage demonstrates high stability and consistency, suitable for high-speed automated production lines to meet the strict requirements of large-scale pharmaceutical packaging. |

Advantages of Gold-Coated Aluminium Blister Foil

| Advantage | Detailed Description |

| Exceptional Protective Performance | Gold-Coated Aluminium Blister Foil provides excellent barrier properties, effectively blocking oxygen, moisture, and light, thereby extending the shelf life of medications and ensuring the stability of their active ingredients. |

| Compatibility with Various Substrates | Gold-Coated Aluminium Blister Foil is compatible with various substrates like PVC, PVDC, and PP, meeting the heat-sealing requirements of different pharmaceutical packaging forms. Its strong seal prevents contamination from the external environment, providing reliable protection for medications. |

| Enhancing Brand Image | The luxurious golden coating enhances the product's appeal, making it particularly suitable for high-end pharmaceutical products and branded medication packaging. It supports multi-color printing to showcase exquisite designs, brand logos, and anti-counterfeiting information, further improving consumer trust and brand recognition. |

| Eco-Friendliness and Safety | Gold-Coated Aluminium Blister Foil uses non-toxic and eco-friendly coatings, meeting modern pharmaceutical packaging safety standards and ensuring safe contact with medications. Its production process has minimal environmental impact, aligning with the principles of green and sustainable development, making it a preferred eco-friendly packaging material in the pharmaceutical industry. |

| High Production Efficiency and Consistency | Gold-Coated Aluminium Blister Foil demonstrates high stability during production and processing, suitable for large-scale pharmaceutical packaging demands. Its excellent thickness uniformity, coating durability, and compatibility provide customers with efficient and reliable production solutions while reducing waste and defect rates during processing. |

| Broad Application Range | Gold-Coated Aluminium Blister Foil is suitable for blister packaging of capsules, tablets, and granular medications. Its superior performance in high-end and branded pharmaceutical packaging meets the higher market demands for packaging appearance and protective properties. |