Paper aluminum pharmaceutical composite film

Paper-aluminum medicinal composite film is a type of composite material made by combining paper and aluminum foil. It is widely used in various fields such as pharmaceuticals, food, beverages, and more.

| Item | Description |

| Commonly Known As | Paper Aluminum Pharmaceutical Composite Film |

| Product Characteristics | The product has good heat sealing, printing properties, and stiffness. It also provides excellent gas and water barrier properties, ensuring a long warranty period for drugs. |

| Applications Range | Widely used in food, beverages, cigarettes, pharmaceuticals, photographic base plates, household daily necessities, etc. |

| Additional Features | Resistant to corrosion, with strong barrier, moisture-proof, waterproof, excellent air tightness, and fragrance retention. |

Paper-AL-PE Composite Film is a high-performance packaging material made from a multilayer composite structure of paper-based material, aluminum foil, and polyethylene (PE). It is primarily used for pharmaceutical packaging and has widespread applications in industries such as pharmaceuticals, food, beverages, and tobacco.

Due to its unique laminated structure and performance advantages, Paper-AL-PE composite film provides significant benefits in maintaining the quality of medicines, extending shelf life, and enhancing the aesthetic and functional aspects of packaging.

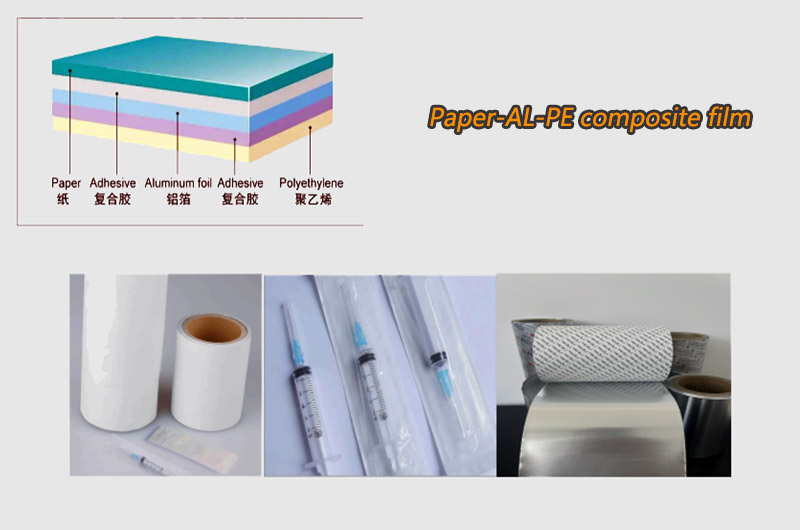

Paper-AL-PE Composite Film Structure

The Paper-AL-PE composite film typically consists of three or more layers of materials, including:

- Paper Layer: The paper material is usually high-quality white paper or kraft paper, providing rigidity and structural support. The paper layer also offers good printability, making the packaging more attractive.

- Aluminum Foil Layer: The aluminum foil layer, located in the middle or inner layer, provides excellent barrier properties against gases and water vapor. This layer effectively prevents the ingress of air, moisture, and oxygen, ensuring the freshness and stability of the contents.

- Polyethylene (PE) Layer: The PE layer is typically located on the outer surface of the composite film, providing heat sealability, tear resistance, and good mechanical strength. PE offers excellent heat sealing properties, ensuring a secure closure during the packaging process.

Paper-AL-PE Composite Film Features

- Excellent Heat Sealability: The PE layer provides excellent heat sealing properties, allowing the packaging bags to be securely sealed during production, preventing the entry of air, moisture, etc.

- Good Printability: The presence of the paper layer gives the composite film good printability, making it suitable for various patterns, text, and branding logos, enhancing the product's market competitiveness.

- Strong Barrier Properties: The aluminum foil layer provides excellent gas, moisture, and water vapor barrier properties, effectively extending the shelf life of medicines, food, and other products, and ensuring the contents are protected from environmental factors.

- Moisture and Water Resistance: The composite film exhibits excellent moisture and water resistance, making it suitable for products that need to remain dry or are packaged in humid environments.

- Fragrance Retention: The aluminum foil layer’s sealing properties help preserve the fragrance of products, which is particularly important for food and tobacco products.

- Corrosion Resistance: The aluminum foil layer has strong corrosion resistance, preventing external substances from penetrating and degrading the film material.

- Good Rigidity and Toughness: The combination of the paper layer and PE layer gives the composite film certain rigidity and tensile strength, enabling it to withstand external forces during transportation without breaking easily.

Paper-AL-PE Composite Film Applications

- Pharmaceutical Packaging: Widely used for packaging various pharmaceuticals, especially those requiring long shelf life, such as tablets, capsules, and oral liquids. These medicines are highly sensitive to moisture, air, and light, and Paper-AL-PE film provides effective protection.

- Food Packaging: Used for packaging items like fresh-keeping bags, candies, coffee powder, spices, etc. The paper-aluminum film effectively isolates oxygen and moisture, preventing food spoilage and maintaining freshness.

- Beverage Packaging: Commonly used for ready-to-drink beverages, juices, and other drinks, ensuring the freshness of the product.

- Cigarette Packaging: Prevents cigarettes from drying out and oxidizing, helping maintain their moisture and aroma.

- Photographic Materials Packaging: Used for packaging precision photographic materials, effectively isolating light and moisture to protect the quality of photographic films.

- Household Goods Packaging: Suitable for packaging household items like cleaning products and wet wipes, providing moisture-proof protection.

Paper-AL-PE composite film in various fields is detailed in the following table. The table outlines the application features and specific functions, showcasing its multiple advantages in different types of packaging.

| Application Area | Specific Description |

| Pharmaceutical Packaging | Barrier against oxygen and moisture, preventing drug oxidation and dampness. |

| Protects from light damage to medicines. | |

| Extends the shelf life of medicines and ensures efficacy. | |

| Suitable for tablets, capsules, oral liquids, and more. | |

| Food Packaging | Isolates oxygen and moisture, keeping food fresh. |

| Retains fragrance, preventing loss of flavor in spices, candies, and coffee. | |

| Moisture-proof and water-resistant, preventing spoilage. | |

| Suitable for candies, coffee powder, seasonings, etc. | |

| Beverage Packaging | Keeps drinks fresh and prevents oxidation. |

| Blocks external contaminants, ensuring hygiene. | |

| Suitable for both cold and room temperature beverages. | |

| Applicable to juice, carbonated drinks, ready-to-drink beverages, etc. | |

| Cigarette Packaging | Prevents cigarettes from drying out and oxidizing, maintaining moisture and aroma. |

| Excellent fragrance retention, extends the aroma retention period. | |

| Strong heat sealability, facilitating automated production line packaging. | |

| Suitable for cigarettes, cigars, and other tobacco products. | |

| Photographic Materials Packaging | Blocks UV and visible light to avoid exposure and fading. |

| Moisture-proof, keeping the material dry and preventing mold. | |

| Provides physical protection, preventing damage during transportation. | |

| Suitable for photographic films and imaging materials packaging. | |

| Household Goods Packaging | Moisture-proof and water-resistant, protecting products from external moisture. |

| Ensures hygiene and safety for items like wet wipes and cleaning products. | |

| Protects chemical contents, preventing leakage or evaporation. | |

| Suitable for wet wipes, cleaning products, detergents, etc. |

Advantages of Paper-Aluminum Pharmaceutical Composite Film

The comprehensive properties of Paper-AL-PE composite film make it highly suitable for demanding packaging requirements, especially in industries such as pharmaceuticals, food, and beverages. Its strong barrier, moisture-proof, and corrosion-resistant properties effectively protect products and extend their shelf life.

HC Aluminum mainly produces aluminum foils used in pharmaceutical packaging (such as blister foil, aluminum foil, strip foil, and suppository foil), as well as various composite films for packaging tablets and food, and aluminum foil paper.