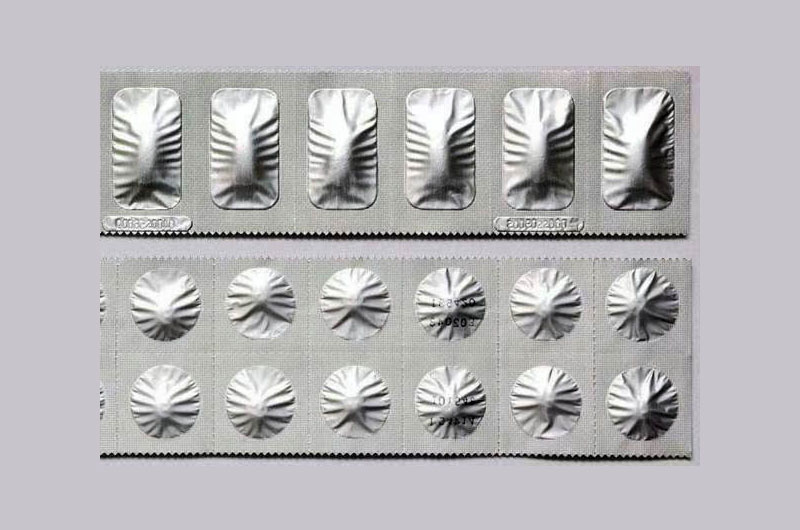

Pharmaceutical Double aluminum easy tear film

Pharmaceutical Double Aluminum Easy Tear Film is a high-performance packaging material that combines easy-tear film and adhesive layer technology, specifically designed for pharmaceutical packaging. This material enhances performance and flexibility, providing an effective solution to improve the shelf life and packaging security of medications.

| Feature | Description |

| Performance | Excellent light avoidance, moisture-proof, anti-oxygen passage, and gas intrusion isolation. |

| Inner Layer Material | PE (Polyethylene) or CPP (Cast Polypropylene) film, providing good heat sealing properties. |

| Sealing Property | The packaging ensures a high level of sealing to maintain the integrity of the medicine. |

| Extended Shelf Life | Designed to extend the shelf life of the drug effectively. |

| Uses | Suitable for tablets, capsules, and other soft double aluminum packaging. |

| Structure Specifications | OP/AL/PE |

| OP/AL/CPP | |

| Easy to tear PET/AL/PE | |

| Easy to tear PET/AL/CPP |

Double aluminum easy tear film is an innovative packaging material that employs advanced easy-tear film and adhesive layer technology, specifically designed to enhance packaging performance, especially in the pharmaceutical field. The main advantage of this film lies in its excellent flexibility and durability, which allows it to effectively protect the products inside the packaging.

This double aluminum easy tear film has multiple outstanding properties, including light blocking, moisture resistance, antioxidant, and gas barrier capabilities. Its unique structural design enables the packaging to effectively block the impact of external environmental factors, ensuring the quality and safety of the pharmaceutical products.

Pharmaceutical Double Aluminum Easy Tear Film Features

- Light Barrier: The double aluminum easy tear film offers excellent light-blocking performance, effectively preventing the intrusion of UV and visible light, thus avoiding the degradation of pharmaceutical products due to light exposure and ensuring the active ingredients are not destroyed.

- Moisture Resistance: This film layer can effectively block moisture, preventing pharmaceutical products from deteriorating due to humidity during storage, maintaining their quality and stability.

- Antioxidant Properties: The aluminum foil structure of the film provides strong antioxidant properties, isolating oxygen from the air, preventing oxidation of the pharmaceutical products, and extending their shelf life.

- Gas Barrier: Its excellent gas barrier properties prevent harmful gases in the air from entering the packaging, reducing the contact between the pharmaceutical products and the external environment, effectively protecting the product quality.

- Good Heat Sealing: The inner layer uses polyethylene (PE) or polypropylene (CPP) film, which has excellent heat sealing properties, ensuring good sealing of the packaging and effectively preventing the intrusion of external contaminants.

- Flexibility and Easy Tear: The film has excellent flexibility and easy-tear properties, allowing consumers to easily open the packaging without damaging the product. Its "easy tear film" technology makes pharmaceutical packaging more convenient and practical.

- UV Resistance: The aluminum foil layer effectively blocks UV rays, protecting the packaging from UV exposure.

- Good Printability: The polyethylene film layer can be printed, allowing it to be processed into various colors and patterns.

Pharmaceutical Double Aluminum Easy Tear Film Specifications

| Double aluminum easy tear film raw material pe film pe lamination film | |

| Thickness | 45-110mic |

| Alloy | 8011 |

| Use | pharmaceutical |

| Temper | soft |

| Width | 30-650mm |

| Certification | SGS/ISO/CFDA/DMF |

| Printing | Can be customized |

| Structure | AL/PE or PVC/PE |

Pharmaceutical Double Aluminum Easy Tear Film Structure

In terms of structure, the inner layer typically uses polyethylene (PE) or polypropylene (CPP) film. These materials have excellent heat sealing properties, ensuring that the packaged pharmaceutical products achieve superior sealing, thereby extending the shelf life and maintaining the stability of their active ingredients.

In terms of specific structural specifications, the double aluminum easy tear film can be customized based on different needs. Common combinations include: OP/AL/PE, OP/AL/CPP, Easy Tear PET/AL/PE, and Easy Tear PET/AL/CPP. These combinations not only meet the packaging requirements for various products but also provide outstanding protective performance.

- OP/AL/PE: The outer layer is an OPP film, the middle layer is aluminum foil, and the inner layer is a PE film, suitable for packaging a wide range of common pharmaceutical products.

- OP/AL/CPP: The outer layer is an OPP film, the middle layer is aluminum foil, and the inner layer is a CPP film, offering stronger sealing and tear resistance, suitable for high-performance pharmaceutical packaging.

- PET/AL/PE: The outer layer is a PET film, the middle layer is aluminum foil, and the inner layer is a PE film, providing better stretch resistance, ideal for packaging specialized pharmaceutical products.

- PET/AL/CPP: The outer layer is a PET film, the middle layer is aluminum foil, and the inner layer is a CPP film, combining higher strength and excellent sealing properties, suitable for high-performance packaging.

Advantages of Double Aluminum Easy Tear Film

Below are the main advantages of the double aluminum easy tear film in pharmaceutical packaging, displayed in a table:

| Advantage | Detailed Description |

| Extends Shelf Life | By effectively isolating gases, preventing moisture, and blocking light, the double aluminum easy tear film significantly extends the shelf life of pharmaceuticals, preventing external factors like moisture, oxygen, and light from affecting the stability of the products. |

| High Security | The sealing and antioxidant properties of the film layer ensure that the packaged pharmaceuticals are protected from external environmental influences, enhancing the safety of the products and preventing the degradation or loss of efficacy of the active ingredients. |

| Convenience | The easy-tear film design makes it more convenient for consumers to access the medication without the need for additional tools, making the packaging process more comfortable and user-friendly. |

This table summarizes the key advantages of the double aluminum easy tear film in extending the shelf life, ensuring the safety of pharmaceuticals, and increasing consumer convenience.

Double Aluminum Easy Tear Film Applications

The double aluminum easy tear film is a high-performance packaging material widely used in the pharmaceutical, health supplement, and food packaging industries. It is particularly suitable for packaging tablets, capsules, soft gels, and other pharmaceutical products. This packaging material uses a double-layer aluminum film structure that combines the excellent barrier properties of aluminum with the convenience of easy-tear film, providing ideal protection for pharmaceuticals and other products.

First, the double aluminum easy tear film effectively prevents moisture, oxygen, and light from entering, providing excellent moisture resistance, oxidation protection, and gas barrier capabilities. These properties are crucial for maintaining the stability and integrity of the active ingredients in pharmaceuticals. During long-term storage, it prevents degradation or loss of efficacy caused by external environmental factors, ensuring the drug’s effectiveness is not compromised.

In addition to pharmaceuticals, the double aluminum easy tear film is also widely used in food and health supplement packaging. It effectively extends the shelf life of products, preventing air, moisture, and other factors from impacting the freshness and activity of the items. For health supplements or delicate foods that need to be preserved for long periods, this film material offers a safer and more reliable packaging solution.

In addition to its excellent protective features, the double aluminum easy tear film also offers high consumer convenience. Its easy-tear properties allow consumers to open the packaging easily without the need for tools like scissors, making it a more hassle-free experience. Furthermore, the aluminum foil's tear resistance and high strength ensure the packaging remains intact during transportation and storage, further enhancing the packaging’s security.

The double aluminum easy tear film is a premium packaging material that combines protection, convenience, and safety. It not only provides ideal protection for pharmaceuticals, health supplements, and food but also improves the consumer experience. It is an essential material in the modern packaging industry.

HC Aluminum mainly produces aluminum foils used in pharmaceutical packaging (such as blister foil, aluminum foil, strip foil, and suppository foil), as well as various composite films for packaging tablets and food, and aluminum foil paper.