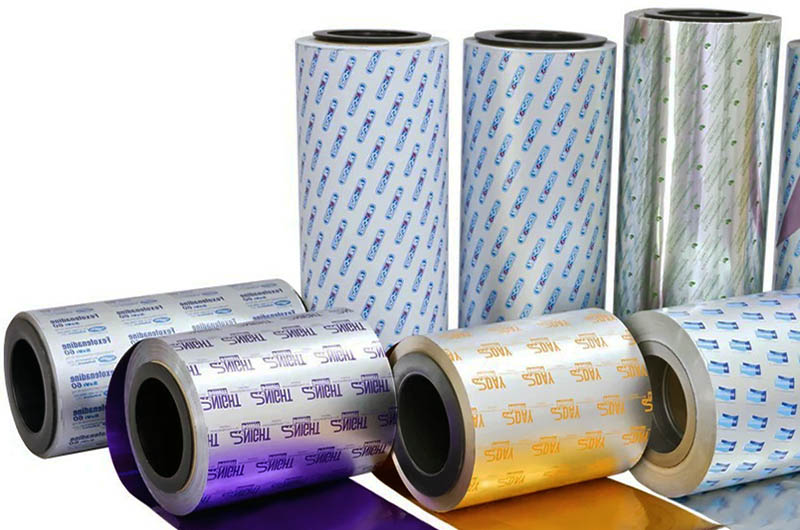

Pharmaceutical-Grade Aluminium Foil for Capsule and Blister Pack

Pharmaceutical-grade aluminium foil is a high-performance packaging material, playing an important role in the pharmaceutical industry due to its excellent barrier properties and adaptability, especially for blister packaging of capsules and tablets. This aluminium foil offers unparalleled gas and moisture barrier performance, strong light resistance, and prevents the medicine from moisture, oxidation, or deterioration, ensuring the stability of its efficacy.

Pharmaceutical-grade aluminium foil is made from alloys such as 8011-H18 or 8021-H18. With its high-efficiency barrier performance, stable heat sealing effect, and flexible processing adaptability, it has become the preferred material for blister packaging of capsules and tablets.

8011 and 8021 are the most common choices, suitable for most pharmaceutical packaging needs, while 8079 and 1235 are available for high-end pharmaceuticals.

Pharmaceutical-Grade Aluminium Foil Alloys and Technical Information

Typical Alloys for Pharmaceutical-Grade Aluminium Foil

| Alloy Model | Temper | Features | Typical Applications |

| 8011 | H18 | Excellent gas and moisture barrier properties | Capsule and tablet packaging |

| Good heat sealing performance | |||

| High strength and cost-effective | |||

| 8021 | H18 | Superior barrier properties (better than 8011) | High-end pharmaceuticals, powder drug packaging |

| Strong chemical resistance | |||

| Suitable for packaging high-sensitive drugs | |||

| 8079 | H18 | Excellent flexibility | Blister packaging, special shape drug packaging |

| Adaptable to complex shape packaging | |||

| Excellent corrosion resistance | |||

| 1235 | O | High-purity aluminium foil | Packaging for tablets and capsules with high barrier requirements |

| Excellent moisture barrier properties | |||

| Excellent flexibility | |||

| 1145 | O/H18 | Made from pure aluminium with high corrosion resistance | Capsule packaging in the medical industry |

| Good formability and oxidation resistance |

Main Technical Parameters of Pharmaceutical-Grade Aluminium Foil

| Parameter Category | Parameter Range | Function Description |

| Thickness | 20μm - 30μm | Choose according to pharmaceutical packaging requirements; increasing thickness improves barrier performance |

| Width | 50mm - 600mm | Meets the needs of different packaging production lines |

| Pinhole Density | ≤0.01% | Ensures the integrity of the packaging with no tiny leaks |

| Tensile Strength | ≥120 MPa | Improves the mechanical performance of the packaging, preventing tearing or damage during transportation |

| Surface Coating Type | No coating, varnish coating, heat seal coating | Provides protection or facilitates bonding with PVC, PVDC, and other materials |

| Elongation | ≥1.0% | Ensures flexibility, adapts to complex mold forming |

| Gas Barrier Properties | Oxygen permeability ≤0.001 cm³/(m²·24h) | Provides the best oxygen barrier effect |

| Moisture Permeability | ≤0.01 g/(m²·24h) | Effectively blocks moisture to prevent drug deterioration |

| Heat Seal Temperature | 160℃ - 200℃ | Provides good heat sealing effect, adapts to high-speed production lines |

Pharmaceutical-Grade Aluminium Foil Features and Functions

Excellent Barrier Properties

Pharmaceutical-grade aluminium foil provides a complete barrier against gases, water vapor, and light, effectively protecting medicines from oxidation, moisture, and UV rays, thus extending their shelf life.

High Surface Quality

The surface is smooth, free from pinholes, cracks, or impurities, providing optimal sealing performance for pharmaceutical packaging while meeting strict industry certification standards such as ISO and FDA.

Chemical Resistance

Aluminium foil does not react chemically with various pharmaceutical ingredients and will not release harmful substances, ensuring the safety of the packaging.

Heat Sealing Properties

Aluminium foil can form a strong heat seal with various substrates (such as PVC, PVDC), ensuring a leak-proof seal.

Flexibility and Processability

Aluminium foil is flexible, making it suitable for high-speed production lines and adaptable to different mold shapes, meeting the needs of complex packaging.

Pharmaceutical-Grade Aluminium Foil Processing Methods

Heat Sealing Process

Aluminium foil is coated with a heat seal layer and forms a strong seal with PVC, PVDC substrates. The heat seal strength ensures moisture and gas barrier properties.

High-Speed Production Adaptability

Thanks to its flexibility and strength, aluminium foil is compatible with high-speed blister packaging equipment, reducing downtime and improving production efficiency.

Precision Slitting and Stamping

Aluminium foil boasts excellent processability, meeting the cutting and stamping requirements of different molds to ensure precise packaging dimensions.

Pharmaceutical-Grade Aluminium Foil Advantages

Protection of Medicines: Excellent barrier properties extend the shelf life of medicines and ensure their efficacy.

Reliable Quality: Complies with international pharmaceutical industry standards, being environmentally friendly and safe.

Economic Efficiency: Strong adaptability to high-speed production lines, reducing packaging costs.

Diverse Applications: Meets the blister packaging needs for various medicines and dietary supplements.

Pharmaceutical-Grade Aluminium Foil for Capsule and Blister Pack Applications

Pharmaceutical capsules and blister packaging play a crucial role in the storage and transportation of medicines. Pharmaceutical-grade aluminium foil, with its excellent barrier properties, heat sealing abilities, and protective functions, is widely used for packaging capsules, tablets, and powder medications, ensuring the quality, stability, and safety of medicines.

Pharmaceutical Capsule Packaging

| Feature | Description |

| Gas and Moisture Barrier | Aluminium foil provides excellent gas and moisture barrier properties, preventing medications from being affected by oxygen and moisture, maintaining their stability. |

| Light Protection | Aluminium foil effectively blocks ultraviolet rays, preventing the degradation of light-sensitive medications. |

| Enhanced Drug Stability | The seal provided by aluminium foil ensures that drugs are not affected by external conditions during transport and storage, maintaining long-term stability. |

| Heat Sealing Properties | Aluminium foil forms a strong heat seal with PVC, PVDC, and other substrates, ensuring the sealing of capsule packaging and preventing leakage or contamination. |

| Packaging Form | After being sealed with aluminium foil, capsules maintain the integrity of the medication, and the packaging protects the product from external contamination. |

| Application Scenarios | Primarily used for packaging common drugs and dietary supplements such as vitamins, minerals, herbal supplements, antibiotics, painkillers, and anti-inflammatory medications. |

Blister Packaging

| Feature | Description |

| Single-Dose Packaging | Each blister unit can package a single dose of medication, ensuring patients take the correct dosage, making medication distribution and management more convenient. |

| Good Sealing Properties | Aluminium foil, when heat-sealed with PVC, PVDC substrates, prevents the entry of air, moisture, and contaminants, ensuring the quality of the medication. |

| Anti-Counterfeiting Feature | Blister packaging with aluminium foil can incorporate anti-counterfeiting features, enhancing the security of medicines and preventing counterfeit products from entering the market. |

| Customizable Design | The shape and size of blister packaging can be customized based on the type of medication, accommodating different drug packaging needs (e.g., round, oval, rectangular, etc.). |

| Light Protection | Aluminium foil effectively blocks UV rays, protecting light-sensitive medications from light-induced degradation. |

| Improved Patient Compliance | Clear labeling on each blister unit, such as drug name, dosage, usage instructions, helps patients take their medication correctly, improving treatment adherence. |

| Packaging Form | Suitable for packaging tablets, capsules, powder medications, etc., ensuring that the packaging is tight and secure. |

| Application Scenarios | Widely used for packaging medications such as vitamins, antibiotics, painkillers, antipyretics, over-the-counter drugs, and dietary supplements. |