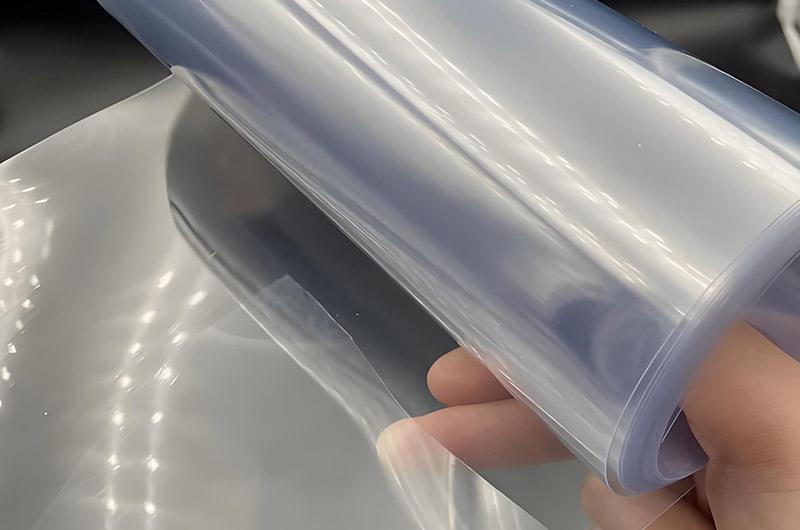

Pharmaceutical PVC Film

Pharmaceutical PVC film is a sterile and non-toxic packaging material made primarily from polyvinyl chloride (PVC) resin through calendaring or blow molding processes. Stabilizers, plasticizers (such as DOP), and barrier materials (such as polyvinylidene chloride/PVDC) are typically added as modifying components to meet the special requirements of pharmaceutical packaging.

Pharmaceutical PVC (polyvinyl chloride) film is a specialized packaging material widely used in the healthcare industry to protect and preserve medicines, medical devices, and other sensitive products. Its unique properties make it the preferred choice for blister packaging, ensuring product integrity and patient safety.

Pharmaceutical PVC film is widely used in blister packaging, pharmaceutical containers, and other primary packaging for solid dosage forms such as tablets and capsules. It must be non-toxic, have low extractables, and be safe for direct contact with medications.

| Category | Details |

| Features | Uniform thickness |

| Transparent and clean | |

| Impact resistance | |

| Easy for forming | |

| Excellent sealing performance | |

| Usage | Blister packaging for medicine tablets, capsules, and pills |

| Oral liquid bottle tray | |

| Food packaging | |

| E-cigarette blister packaging | |

| Main Products | Transparent sheet / Color sheet with varying width and thickness |

| Thickness | 0.20mm - 0.60mm |

| Width | 80mm - 1000mm |

| Diameter | 275mm - 500mm |

PVC film aluminum blister packaging is a widely used material for packaging pharmaceuticals and consumer products, particularly suitable for protecting and displaying tablets, capsules, and other dosage forms.

PVC film, medical PVC hard sheet, is one of the most commonly used and cost-effective materials for pharmaceutical packaging. The material has excellent thermoforming properties and comes in a variety of colors, making it the preferred choice for medications with lower barrier requirements.

Features of PVC Film Aluminium Blister

- Durability: PVC material has high durability, effectively protecting contents from external environmental influences.

- Transparency: The transparent PVC film allows clear visibility of the products inside the packaging, helping to enhance consumer purchasing desire.

- Uniform thickness: The uniform thickness of the PVC film ensures the strength and consistency of the blister.

- Impact resistance: PVC has good impact resistance, helping to prevent packaging breakage.

- Easy forming: PVC material is easy to process and form, suitable for various complex packaging shapes.

- Excellent sealing performance: PVC blisters have good sealing performance, effectively preventing moisture and contaminants from entering the packaging, maintaining product freshness and efficacy.

- Thermoformability: The ability of the film to be heat-formed and molded into the blister cavity is crucial. Unplasticized PVC (rigid PVC) is particularly important due to its stability during the thermoforming process.

- Surface finish: A smooth and uniform surface is essential to ensure proper blister forming and to maintain the barrier properties of the entire packaging.

- Moisture and oxygen resistance: Although regular PVC has moderate barrier properties, the addition of a PVDC coating significantly enhances its resistance to moisture, oxygen, and other gases. This is vital for protecting sensitive drugs that may degrade upon exposure to moisture or oxygen.

| Property Category | Specific Description | Application Advantages |

| Barrier Protection | PVC film has excellent moisture, oxygen, and light resistance | Effectively prevents drug degradation caused by moisture, oxygen, and light, ensuring drug stability and shelf life |

| PVC/PVDC composite material can offer up to 5 times the barrier performance | Especially suitable for moisture-sensitive drugs such as tablets and capsules, extending their shelf life | |

| Transparency and Clarity | High transparency allows users to view contents without opening the package | Facilitates drug identification and quality inspection, improving patient compliance |

| Durability and Flexibility | Resistant to physical damage during transportation and handling | Enhances tamper-resistance and improves transport safety |

| Possesses good thermoforming properties | Easily formed into customized blister cavities to accommodate various dosage forms and strengths | |

| Chemical Resistance | Resistant to acids, alkalis, oils, and other common chemicals | Suitable for various drug formulations, including liquids, ointments, and special component drugs |

Pharmaceutical PVC Film Key Performance Indicators

| Performance Category | Specific Indicators | Description |

| Barrier Properties | Excellent barrier against oxygen, water vapor, and bacteria | Effectively extends the shelf life of pharmaceuticals |

| Water vapor transmission rate ≤ 0.5 g/(m²·24h) | Significantly inhibits moisture penetration, protecting drug stability | |

| Oxygen transmission rate ≤ 50 cm³/(m²·24h·0.1MPa) | Reduces oxidation risk, delays drug degradation | |

| PVC/PVDC composite film provides even better barrier performance | Suitable for pharmaceutical packaging requiring higher barrier standards | |

| Mechanical Properties | Tensile strength ≥ 40 MPa (longitudinal/transverse) | Ensures mechanical stability during processing and transportation |

| Impact resistance passes the drop ball impact test | No more than two pieces should break in either longitudinal or transverse directions, ensuring durability | |

| Thermal Properties | Heat shrinkage controlled within ±6% | Ensures dimensional stability during thermoforming and packaging |

| Heat seal strength ≥ 10 N/15mm | Ensures the sealing integrity of blister packs, preventing leakage | |

| Chemical Stability | Resistant to acids, alkalis, oils, and common disinfectants | Meets the packaging requirements of various pharmaceuticals |

| Suitable for packaging of cytotoxic drugs and nuclear medicine | High resistance to drug erosion and biocompatibility |

Barrier Performance Enhancement

- PVDC Coating: PVC films used in pharmaceutical blister packaging are often coated with polyvinylidene chloride (PVDC) to significantly improve their barrier properties against moisture, oxygen, and light. The coating weight may vary depending on the required performance.

- Multilayer Structure: Some films are produced using multilayer lamination (e.g., PVC/PE/PVDC), where the polyethylene (PE) layer helps to form deeper thermoformed cavities, and the PVDC layer serves as the high-barrier component.

Pharmaceutical PVC Film Common Structural Materials Cross-Sectional Performance Comparison Table

| Item / Performance Index | PVC Monolayer Film | PVC/PVDC Composite Film | PVC/PE/PVDC Multilayer Composite Film |

| Barrier Performance | Basic moisture and oxygen resistance, suitable for drugs with general environmental requirements | Barrier performance increased 5 times, excellent moisture, oxygen, and light protection | Extremely strong barrier, suitable for drugs highly sensitive to humidity and oxygen |

| Water Vapor Transmission Rate (g/m²·24h) | 3.0~5.0 | ≤0.5 | ≤0.3 |

| Oxygen Transmission Rate (cm³/m²·24h·0.1MPa) | 250~300 | ≤50 | ≤40 |

| Transparency | High transparency | Slight decrease in transparency (due to PVDC layer) | Slightly lower than PVC/PVDC, moderate transparency |

| Thermoformability | Excellent, easy to process and form | Good, slightly inferior to monolayer PVC | Good, PE layer provides cushioning, aids forming |

| Heat Seal Strength | Moderate, about 6~8 N/15mm | High, ≥10 N/15mm | Very high, ≥12 N/15mm |

| Mechanical Properties | Tensile strength ≥ 40 MPa, moderate tear resistance | Slightly improved tensile strength, enhanced impact resistance | Excellent overall mechanical strength, high transportation stability |

| Chemical Stability | Resistant to some acids, alkalis, and drugs | Good acid and alkali resistance, broader applicability | Resistant to acids, alkalis, oils, disinfectants, etc., widest applicability |

| Applicable Drugs | General medicines, solid preparations | Tablets, capsules, requiring moderate moisture resistance | High-end preparations, cytotoxic drugs, nuclear medicine |

| Cost | Lowest cost, economical choice | Moderate cost, high cost performance | Higher cost, suitable for high value-added drugs |

Pharmaceutical PVC Film Production Technology

Film Formation Process

- Extrusion: The most common method, where a homogeneous mixture of PVC resin and additives is melted and extruded to form a continuous film. This process allows control over the film thickness (typically between 0.1 to 1.0 mm) and uniformity.

- Calendering: A process where molten PVC is fed between rollers to achieve the desired thickness and surface finish.

- Casting: Sometimes used for producing high-transparency films, where molten resin is cast onto a surface and then rapidly cooled.

Coating and Lamination

- PVDC Coating: Using an emulsion coating process, PVDC resin dispersed in water is evenly coated onto the PVC substrate. Multiple layers can be applied with drying in between to ensure adhesion and performance.

- Lamination: In some cases, PVC film is laminated with other layers (such as PE or PCTFE) to enhance mechanical strength or improve barrier properties.

Pharmaceutical Applications of PVC Film

Pharmaceutical PVC film is primarily used in packaging applications that require strict protection, transparency, and compliance:

PVC Film for Blister Packaging

- Blister Packaging: Mainly used for tablets, capsules, and lozenges, providing unit dose protection.

- Tablet and Capsule Packaging: The film's transparency and thermoformability allow manufacturers to produce blister packs that protect each dose, clearly display product information, and include tamper-evident seals.

- Functional Barrier Layers: PVDC-coated PVC film can form a strong barrier against moisture and oxygen, extending the shelf life of pharmaceuticals.

Other Pharmaceutical Uses of PVC Film

- Medical Device Packaging: Secures syringes, needles, and diagnostic kits while maintaining sterility.

- Cold-Formed Aluminum Foil Sealing: Combined with aluminum foil, used for packaging liquids or suppositories.

- Pharmaceutical Labels and Inserts: The film is often printed with dosage, expiration dates, or tamper-evident information.

- Protective Sleeves: The film can also serve as the outer layer in multi-layer packaging systems, providing additional mechanical protection.

Advantages and Limitations of PVC Film

- Advantages: High transparency, low cost, easy processing; significantly enhanced barrier properties after PVDC lamination.

- Limitations: Pure PVC has limited barrier properties and needs to be combined with other materials; plasticized soft PVC is prone to aging.

Advantages of PVC Film

- Cost-Effectiveness: Compared to other barrier films, PVC film is relatively inexpensive, making it a popular choice for high-volume pharmaceutical applications.

- Excellent Formability: Unplasticized (rigid) PVC is highly suitable for thermoforming into the precise shapes needed for blister packaging.

- Customizability: These films can be easily modified through coatings (e.g., PVDC) or additional layers (e.g., PE) to customize barrier properties for specific products.

- High Transparency: Excellent optical clarity aids in product inspection and brand identification.

- Compliance: Meets FDA, ISO9001, and SGS standards, ensuring non-toxic safety.

Limitations of PVC Film

- Barrier Limitations Without Coating: For highly sensitive products without additional coatings, standard PVC may not provide adequate moisture and oxygen protection.

- Environmental Concerns: PVC can release hydrochloric acid during incineration, posing environmental issues. However, strict manufacturing and disposal protocols help mitigate these problems.

Pharmaceutical PVC film is a fundamental material for solid dosage packaging. Its unique high transparency, thermoformability, barrier properties, and compliance with stringent safety standards make it indispensable for ensuring that pharmaceuticals are protected, clearly presented, and preserved throughout their shelf life. By using advanced coatings such as PVDC, manufacturers can tailor film performance to meet the most demanding pharmaceutical applications, ensuring product integrity and patient safety.

Main Blister Products from HC Aluminum

Transparent sheets: Used for displaying products, commonly seen in pharmaceutical and consumer product packaging.

Colored sheets of varying widths and thicknesses: To meet specific market demands and provide diverse packaging solutions.

- PVC Film Aluminium Blister: Basic blister pack with PVC and aluminum for moisture and light protection.

- PVC/PVDC Film Aluminium Blister: Enhanced barrier properties with PVDC for sensitive products.

- PVC/PE PET/PE Film Aluminium Blister: Multi-layer structure providing a combination of benefits from various plastics, suitable for different applications.

PVC film aluminum blister packaging, with its excellent physical properties and wide range of applications, has become an indispensable packaging solution in many industries. It not only provides effective product protection but also offers good display effects, enhancing the consumer experience.